What does marble slab mean?

1. The meaning of marble slab specifications

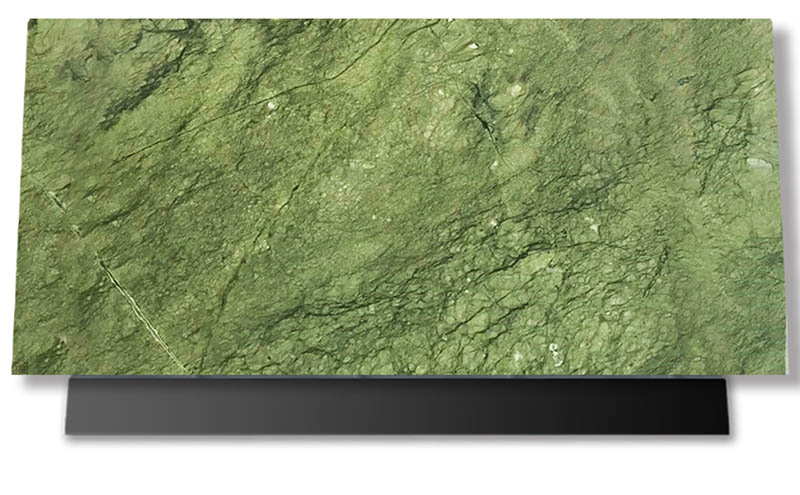

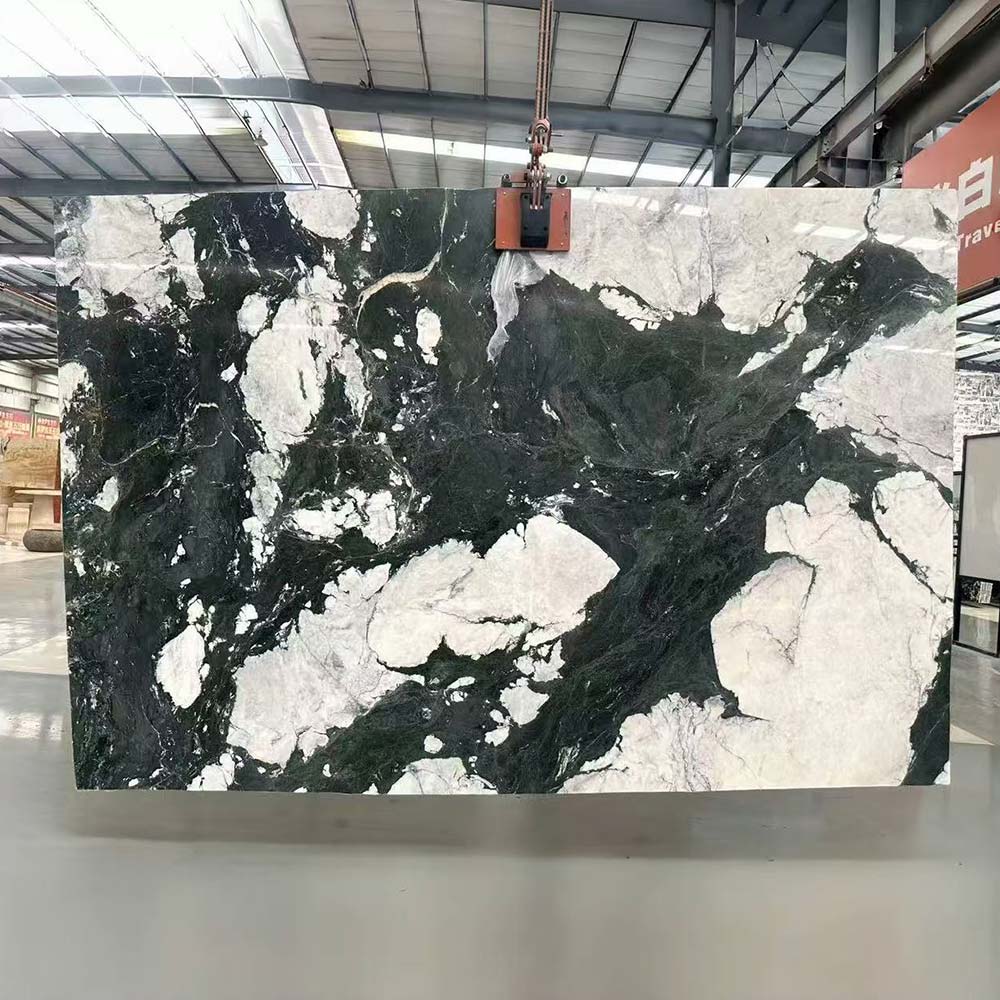

Marble slab refers to a stone processing method, which is to cut the original marble stone into specified sizes and turn it into regular marble slabs. The specifications of marble slabs refer to the standard size of these slabs. Normally, the specifications of marble slabs are 2.6 meters long, 1.32 meters wide, and 1.8 centimeters thick.

2. The manufacturing process of marble slabs

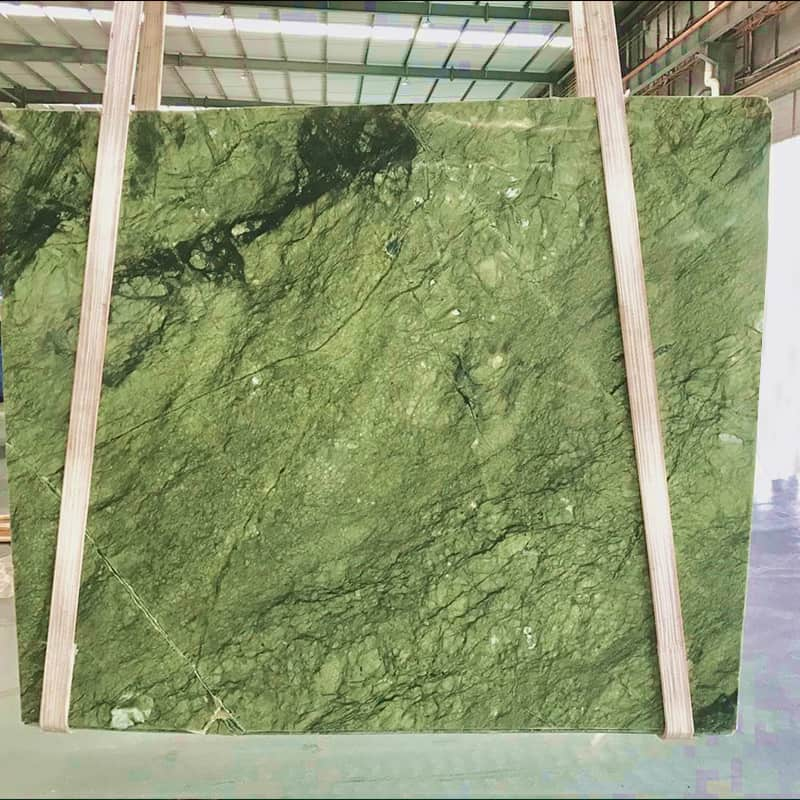

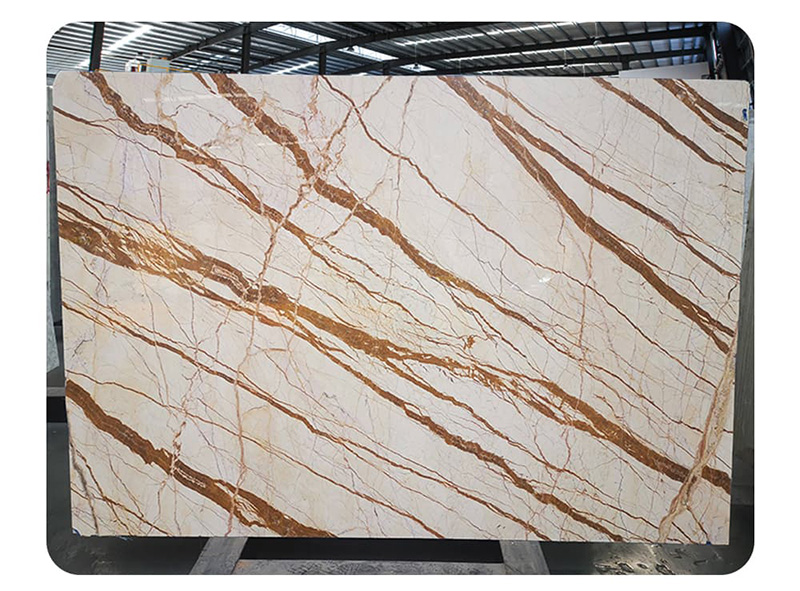

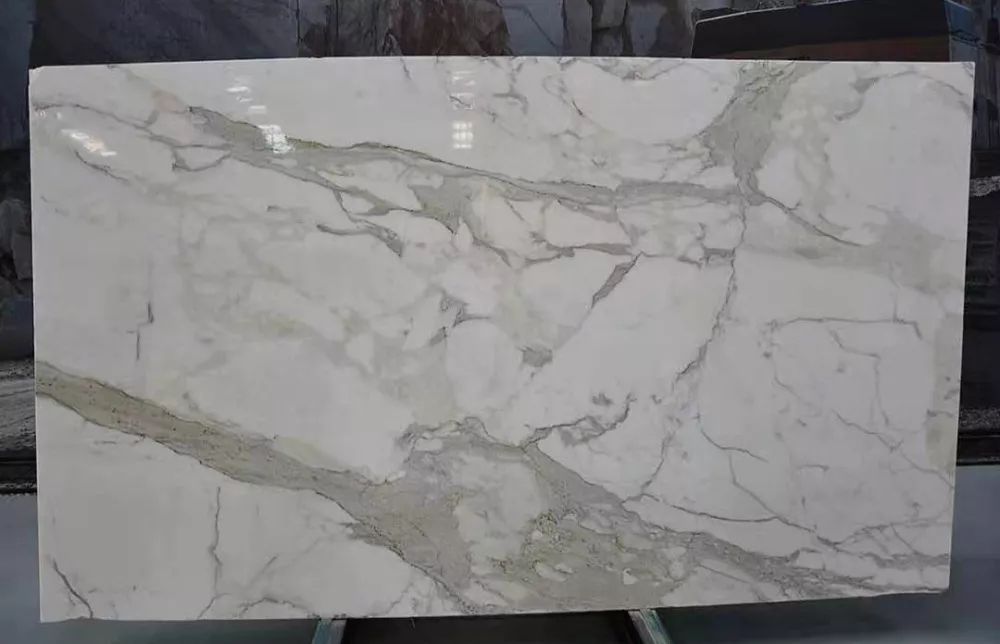

The production process of large marble slabs is relatively complicated and generally requires the following steps: First, material selection, which must have clear texture, white color, no cracks, and flawless raw materials; the next step is cutting, using high-tech marble The cutting machine performs cutting to ensure the perfection and specification of the cutting; then polishing, using different polishing processes, pays attention to every detail to ensure the gloss of the large plate. The last step is packaging. The finished marble slabs are carefully packaged for transportation.

3. Uses of marble slabs

Marble slabs can be widely used in building decoration, home decoration, carving technology, etc. Because marble itself has excellent texture, and both color and texture can add a lot of color to a space, it has been widely used in architectural decoration, such as floors, walls, countertops, pillars, etc. made of marble. In terms of home decoration, you can use large marble slabs to make desktops, coffee tables, TV cabinets, etc. to increase the nobility and elegance of the entire space.

In short, marble slab specifications refer to the standard size of marble slabs, which have a great impact on the application and technology of marble products. For consumers who buy marble products, understanding the specifications of large marble slabs and their production technology is the key to purchasing high-quality marble products.